To inspect the internal conditions of pipeline with a camera which installed on a wheel tractor and can travel along various type and size of pipeline, the internal condition can be record in from of video and photo.

A1 – CCTV Survey for pipes, drainage, conduit and watermains

A2 – Men Entry Survey for Culvert, Tunnel and other Confined Space work place

Our Services

A. Conduit Condition Evaluation (CCTV and ME Survey)

管道狀況評價(排水)

B. Manhole Internal Condition Survey (MHICS)沙井狀況評價

To Investigate manholes & to provide detailed information for the design and construction of drainage works and data are recorded in a standardized Manhole Card.

B1 – Manhole Structural Survey

B2 – Expedient Connection (EC) Survey

C. Utility Survey (Pipe Cable Locator Survey, PCL)管綫測量(PCL)

To locate and identify all underground utilities, including power and telephone cables, gas, water, drainage and waste pipes, by Non-destructive method and provide utility mapping with the depth and position of these utilities.

C1 – Utility Survey for underground utilities

C2 – Cable Detection by Competent Person (CP) under Cap.406H

C3 – Topographical Survey

D. Water Leakage Detection and Control漏水監控

To monitor, control, locate, localize and pin-point any suspected leaks from any pressurized water supply system.

D1 – Leak Noise Correlation (LNC) Survey by Acoustic Method

D2 – Minimum Night Flow Test (MNFT)

D3 – Hydrogen Gas Leak Detection

D4 – Pressure Management & Control

E. Advanced Leakage Detection of Buried Water Carrying Services Affecting Slopes斜坡管道測漏

To inspect and testing of Buried Water Carrying Services in Slope and Hillsides – Checking Typcial Slope Condition. To inspect the potential risk on the slope which affect the stability and the structure of tslope and therefore prevent landslip.

E1 – Buildings Department Dangerous Hill (DH) Order

F. Pipe Rehabilitation by Trenchless Technology管綫維修(非開挖工程技術喉管修補)

To repair the underground pipeline by trenchless method without excavation.

F1 – Full Lining by CIPP method

F2 – Part/Patch Lining

F3 – Joint Seal Repairing method

F4 – Pipe Lining

G. GPR(Ground Penetrating Rader) Survey管綫雷達探測

To detect buried utilities and void on ground and slopes. It produces continuous electromagnetic (EM) waves into underground space. The EM waves carry out the anisotropic information of buried utilities in dielectric parameter, and then reflected back received by antennae.

G1 – Utility Survey

G2 – Void Detection

G3 – Geophysical Survey

G4 – Leakage Detection Survey

G5 – Building Slab Leakage Detection

H. Flow Study in Drainage Conduit流量監控

To inspect the hydraulic suitability and monitoring the flow condition.

H1 – Flow Survey at Drainage, Sewer, Nullah, Open Channel and River

H2 – Level Monitoring

H3 – Riverbed Survey

H4 – Hydrological Survey

H5 – Modeling

I. Pipe Condition Surveys by other non-destructive methods管道狀況評價

To inspect the condition of the underground pipeline in various aspect, such as pipe wall thickness, nternal condition, soil condition, etc.

I1 – Coating Defect Survey (CDS)

I2 – Intensive Ultrasonic Test (IUT)

I3 – Stray Current Survey

I4 – Soil Resistivity Test

I5 – Life Expectancy Survey

J. Utility related Works

J1 – Minor Civil Works for utilities

J2 – Utility related works – Pipe Cutting, Grouting work

K. Civil and Building Works

K1 – Alternation and Additional Works

K2 – Renovation Works

K3 – Fitting Out Works

K4 – Civil Works

K5 – Pumping and Drainage Works

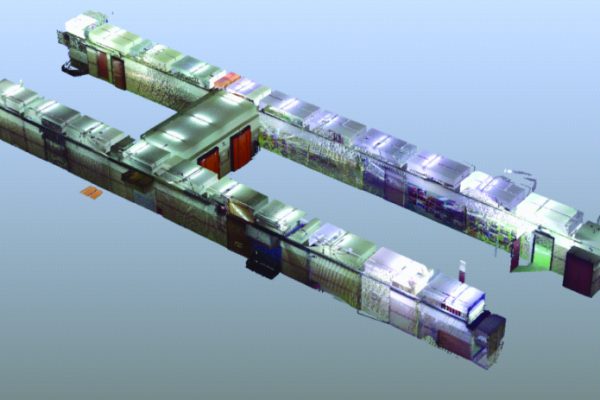

L. 3D Laser Scanning

3D Laser Scanning is also named “real-scene copying technology”, and it can be used as scanning operation in any eqvironment or space. It can directly collect 3D data then rebuild 3D model. Also, the 3D Laser point cloud data can be posted-processed. It is most effective way to get the data of the observed object.

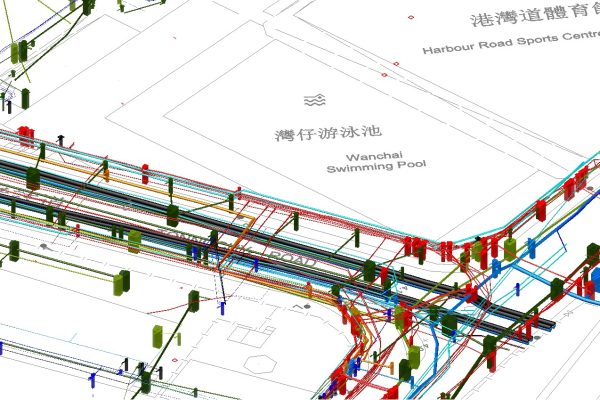

M. 3D Modeling - Building Information Model (BIM)

Through 3D modeling, the hazard of buried utility damage during construction activity can be reduced as the related information of underground infrastructure such as depth, length, diameter, and the exact way they are positioned are revealed. Integrating 3D model into the design process would enable engineer to avoid interferences and clashes with existing underground infrast.